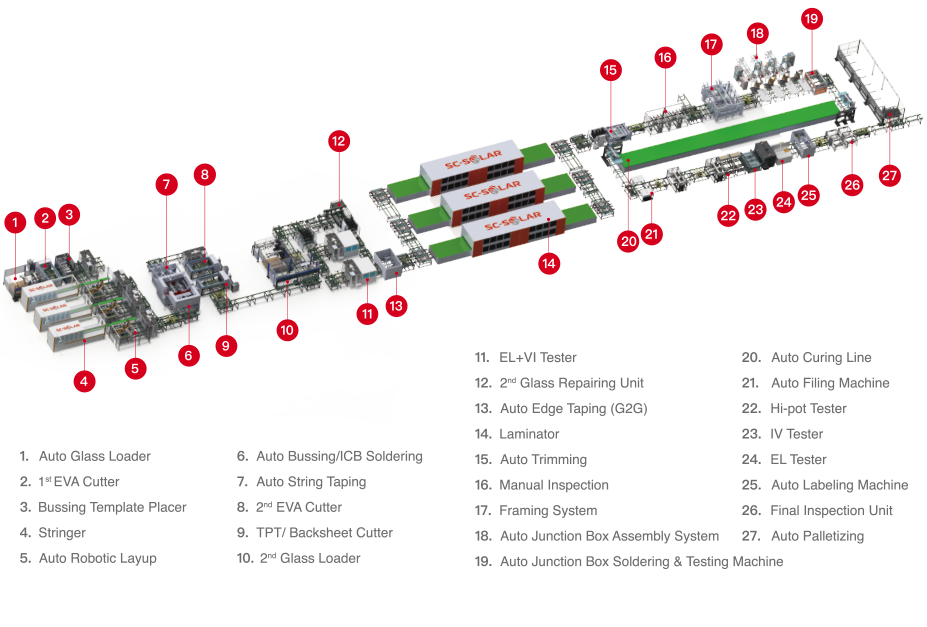

From glass feeding machine, loading template machine, battery string typesetting machine, EVA back panel cutting machine, automatic bus bar welding machine, automatic tape application, double glass laminating machine, automatic edge banding machine, automatic trimming machine, frame mounting All-in-one machines, junction box welding machines, stepped inserting machines, packaging lines, photovoltaic module manufacturing and logistics distribution all use Industry 4.0 to plan the optimal overall production solution for photovoltaic manufacturing.

The Overall Application Configuration Of The Device

△Click to view larger image

Insert Binning Solution

At present, the market is mainly stacked with conventional component equipment, and the double glass components are manually transported.

The PLC tells the robot that there is incoming material through the IO point communication. The robot receives the signal and moves to the grab position. The visual system is notified by TCP/IP communication. The visual system starts to take pictures, and the calculation result is returned to the robot, and the robot completes the grabbing action.

Features

- Compatibility: Double glass inserts, double glass inserts, regular stacks, and conventional reverse stacks.

- Security: CCD vision correction positioning, displacement sensor detection compensation.

- Grab method: vacuum adsorption

- Docking: automatic positioning transmission with automatic packaging line

- Control: Bar code entry, upstream and downstream transmission of MES information