- 中文

- |

- English

- |

- Русский язык

- |

- Español

- |

- Tiếng Việt Nam

- |

- Türkçe

01

Part One

Smart Logistics System Workflow (Video Introduction)

02

Part Two

SHYZ-A-07 Series AGV & SHYZ-A-40 Series AGV

03

Part Three

Stacker

04

Part Four

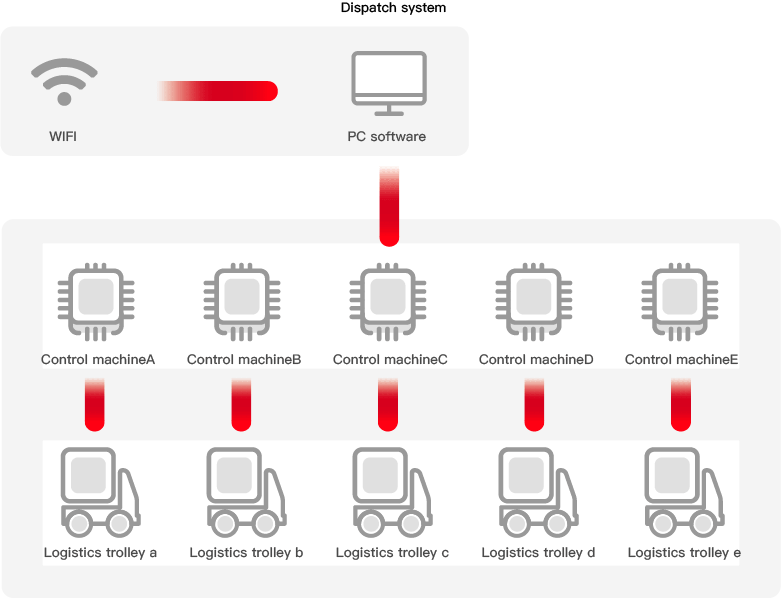

"Top-level scheduling system + smart bicycle system + embedded control system" three-layer control architecture.

The blue ant intelligent logistics robot adopts two-dimensional code vision, and the combination of laser radar and sonic TOF module navigation mode breaks through narrow space restriction barriers, realizes automatic avoidance and autonomous trajectory planning, omnidirectional movement, and efficient intelligent operation. Through the integration of SLAM map establishment and dispatching system, multiple logistics robots can work together at the same time to complete warehousing logistics and intelligent factory logistics tasks.

Appearance size

The SHYZ-A-40 series AGV is mainly developed for the logistics of raw paper in the corrugated paper logistics industry. The body can be omnidirectional and has a hydraulic lifting function. The unique V-groove design can handle large cylindrical objects. Precise device docking is achieved through binocular visual positioning. It adopts high-voltage DC power supply system and has the characteristics of strong endurance. The control system is the same as the SHYZ-A-07 system.

Appearance size

Mechanical properties

Control performance

The blue ant stacker has two models. The visual navigation version needs to be used with the QR code map. It is mainly suitable for workplaces with good environment. The laser navigation version and gravity sensing equipment rely on the natural environment. Map, suitable for workplaces with more dust and waste. The blue ant stacker is a standard stacker body with a maximum moving speed of 1.5m/s and a full load of 0.8~1.2m/s depending on the inertia offset of the center of gravity of the loaded cargo. Rated load 1500kg, optional lead acid battery or lithium battery. Lithium battery supports fast charging, charging time is 2h, running time is full 8h, typical movement is 14h. Optional quick change battery with quick change tool cart.

AGV's "brain" - software control, using: "top-level scheduling system + smart bicycle system + embedded control system" three-layer control architecture. This control architecture enhances the intelligence of a single robot and reduces the workload of central scheduling. The core control unit is the “PICO-IB” controller. Combined with laser radar and industrial cameras to achieve positioning, navigation, scheduling, and operation. Application technologies include: