- 中文

- |

- English

- |

- Русский язык

- |

- Español

- |

- Tiếng Việt Nam

- |

- Türkçe

01

part one

Smart Factory Video Announcement

02

part two

The demographic dividend disappeared, and recruitment is difficult

03

part three

Use technology to save work, and make profits bigger from the roots

04

part four

Provide you with a very proud way of working

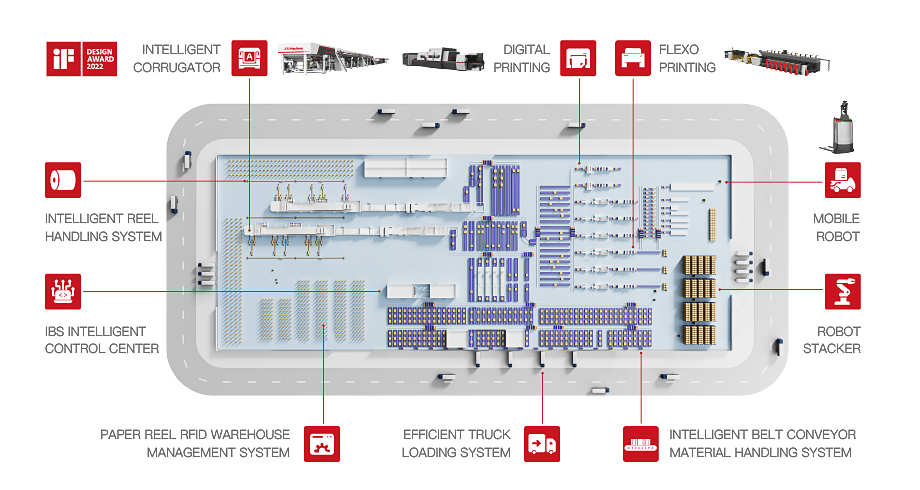

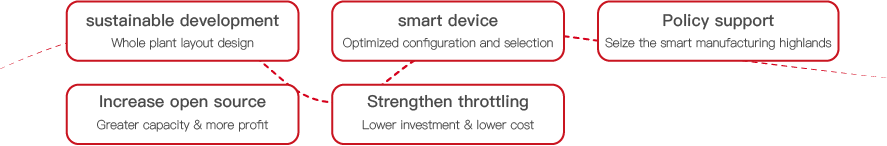

Industry 4.0, China's smart manufacturing trend, the government launched smart manufacturing support policies at different levels of the national, provincial and municipal levels to promote the transformation and upgrading of China's manufacturing industry. Our company provides technical support and cooperation. Enterprise intelligent manufacturing upgrades.

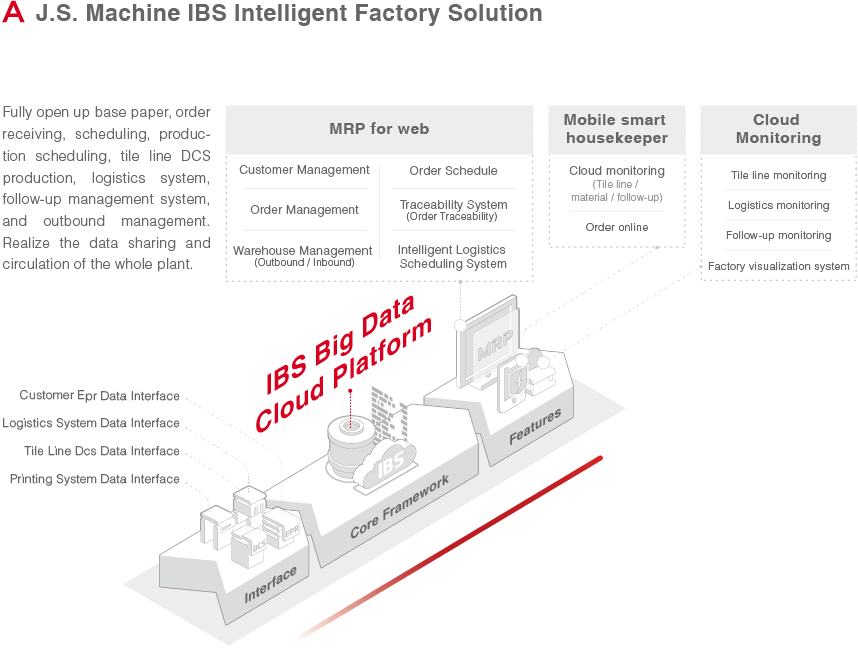

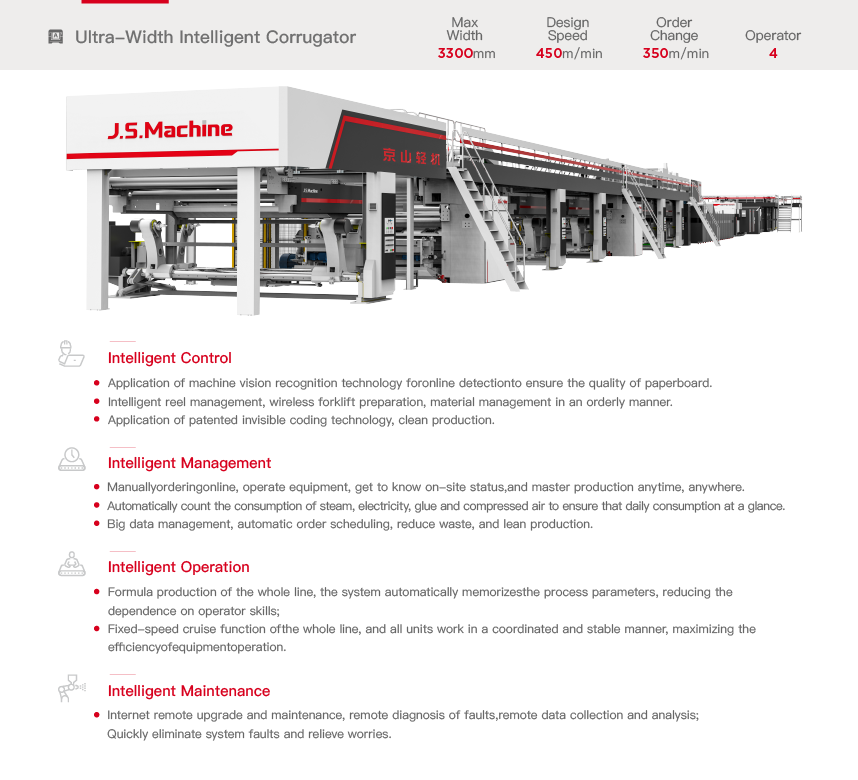

J.S.Machine has been focusing on the packaging industry for more than 40 years. It has continuously innovated and researched and developed a wealth of industry experience. It is the only one in the industry with a whole plant equipment provider, closely surrounding the market and customer needs. Comply with the national intelligent manufacturing, the trend of the industry 4.0 era, with the mission of “making customers' factory management easier, making customers' work more comfortable, and making the boss's investment return higher”, becoming a professional intelligent factory system solution partner around the customer. .

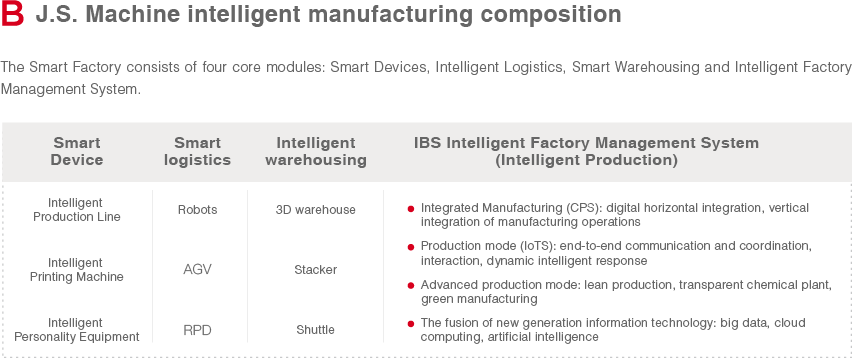

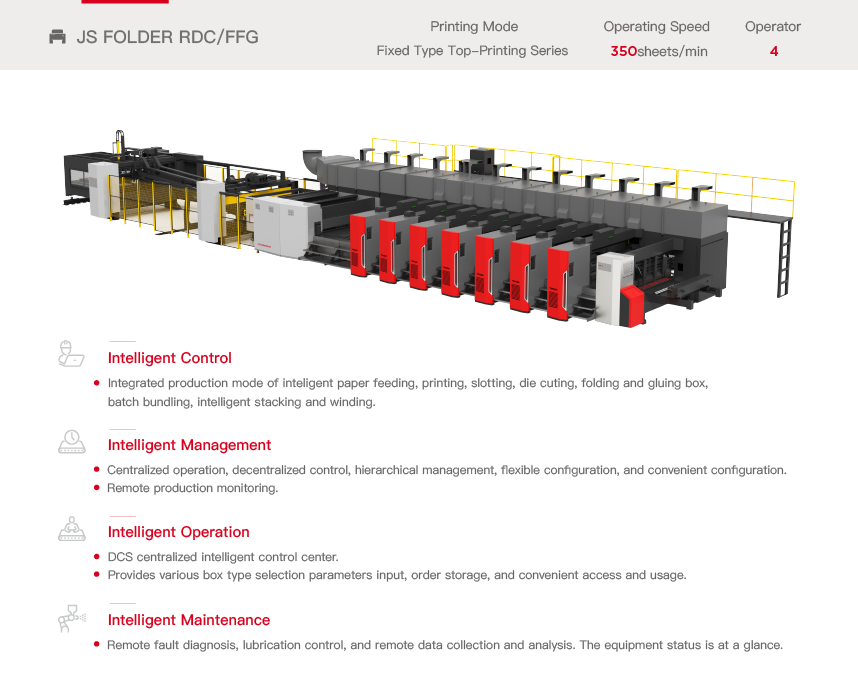

The Smart Factory consists of four core modules: Smart Devices, Intelligent Logistics, Smart Warehousing and Intelligent Factory Management System.