- 中文

- |

- English

- |

- Русский язык

- |

- Español

- |

- Tiếng Việt Nam

- |

- Türkçe

01

part one

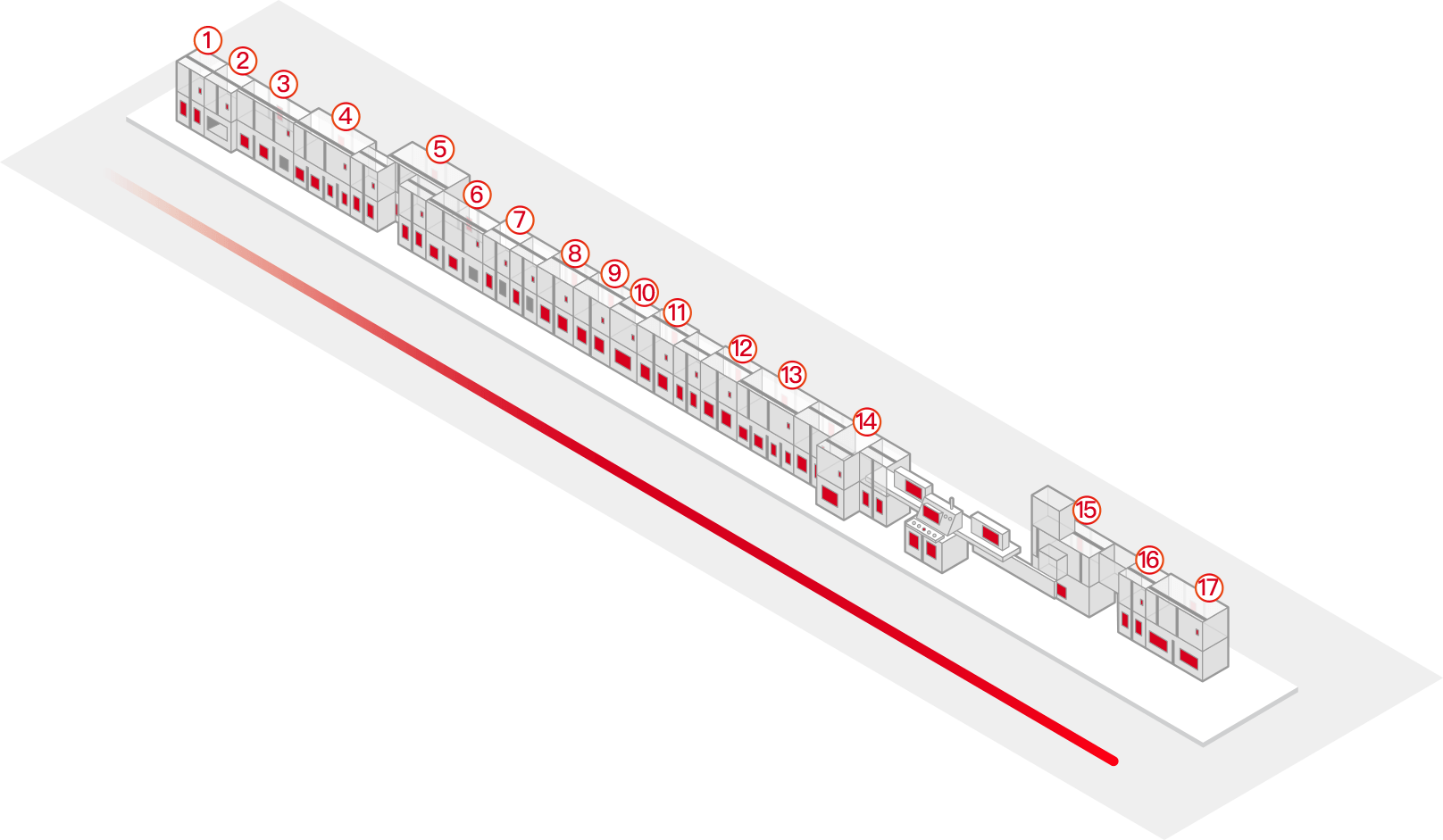

Detailed animation process introduction

02

part two

Equipment specifications: 32.5m(L)* 2.2m(W)* 1.8m(H); automatic scanning machine :1.6m(L)* 1.5m(W)* 1.8m(H)

03

part three

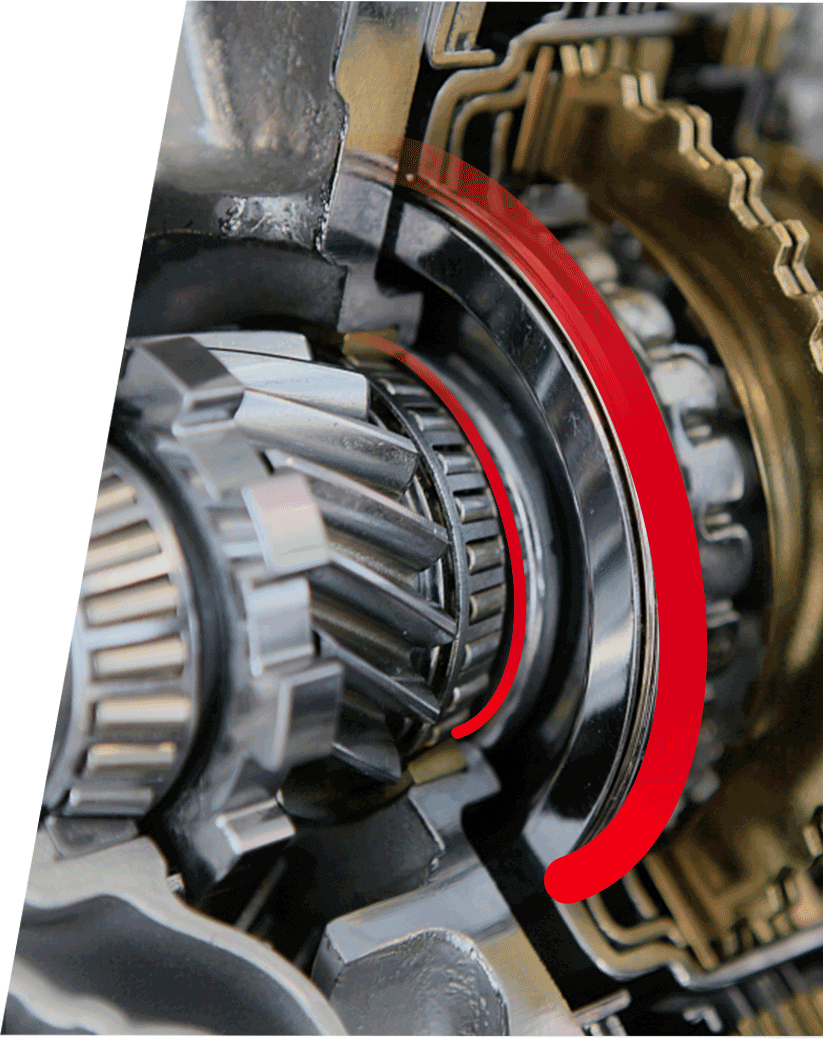

Overall design guidelines and overall design philosophy

04

part four

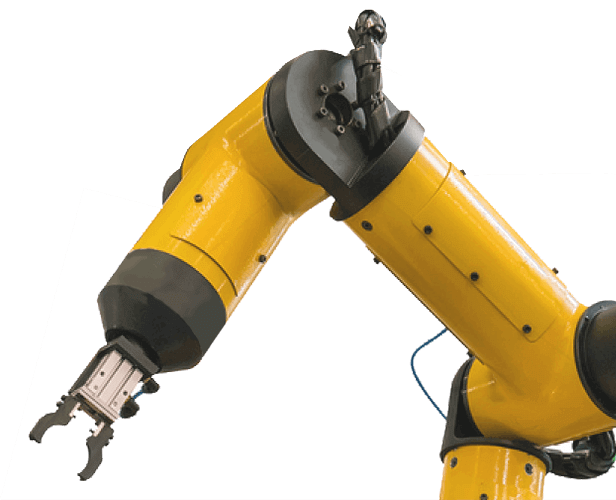

All production data connection real-time upload system

Equipment specifications: total length 32.5M, width 2.2M, height 1.8M; automatic scanning machine (length 1.6m, width 1.5m, height 1.8m)